- Home

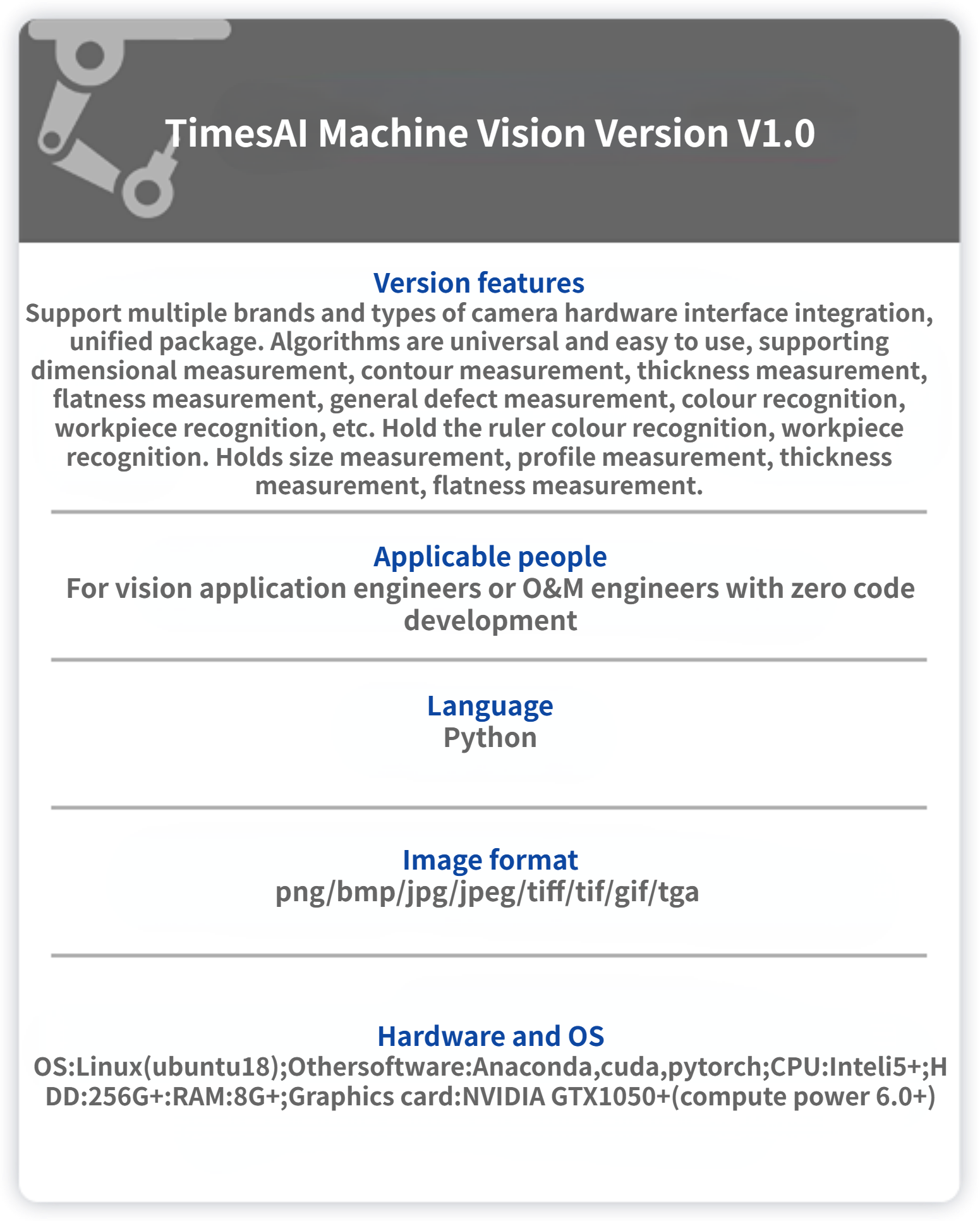

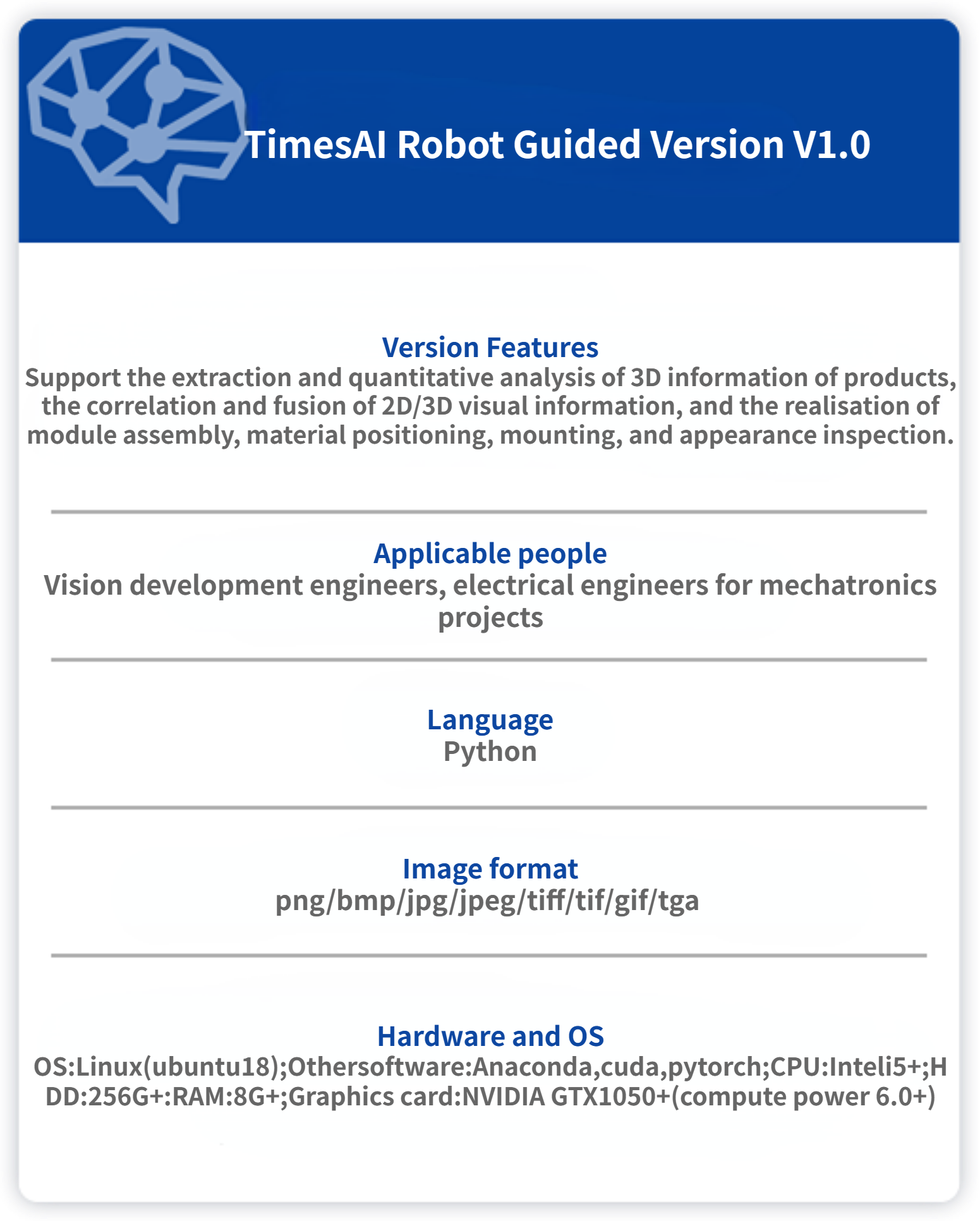

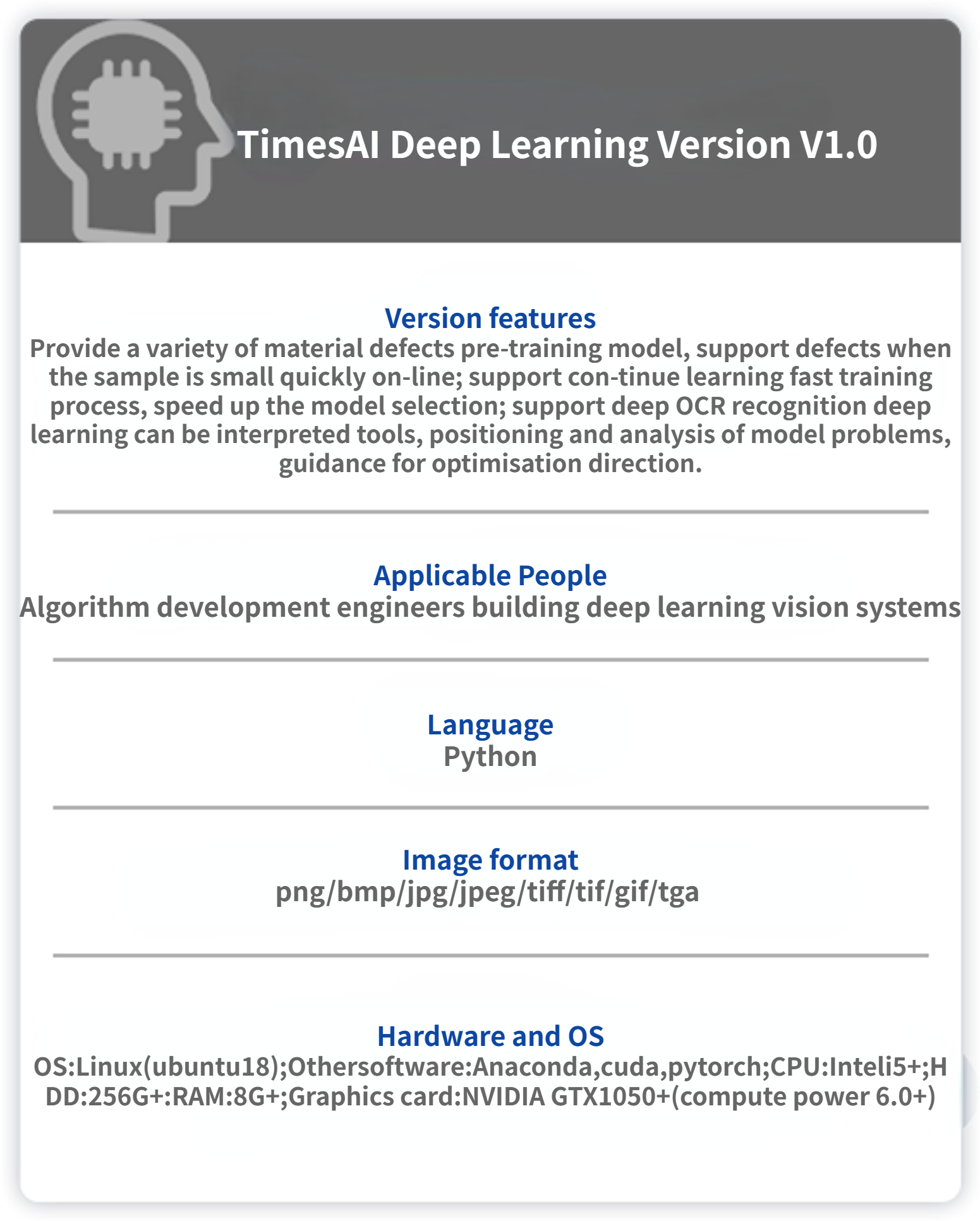

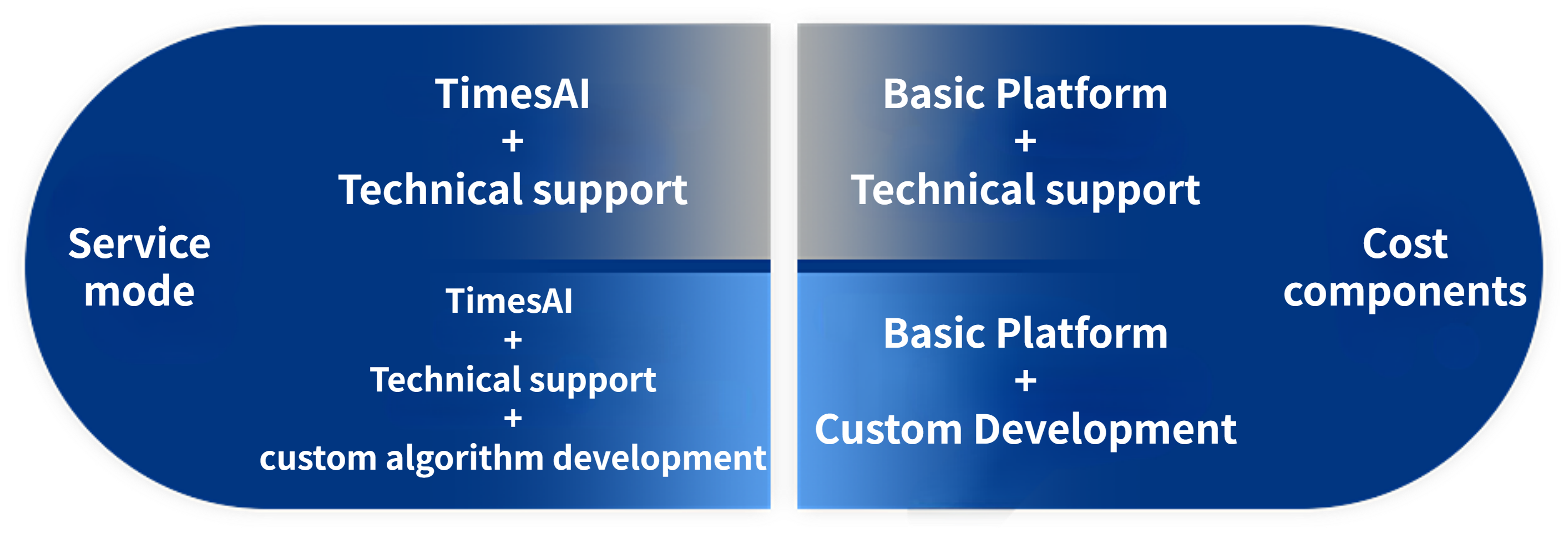

- Al Platforms

- AI Equipments

-

Solutions

- Machine Vision & Deep Learning

- 3D Vision & Smart Guidance

- Big Data & Machine Learning

- Partners

- News

- Career

- About Us