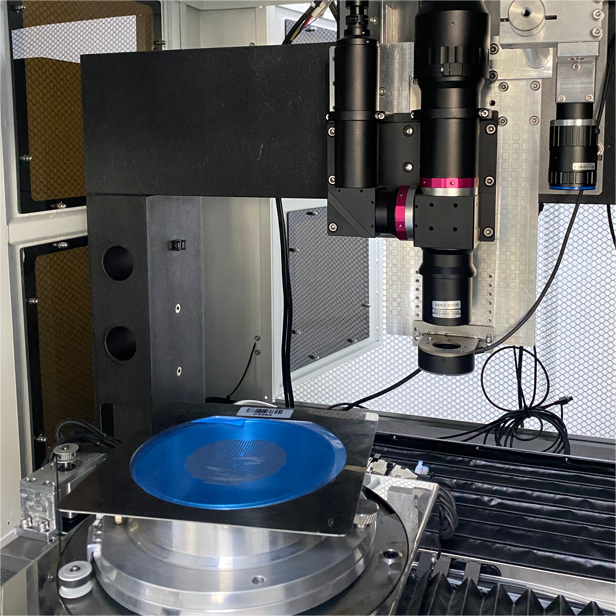

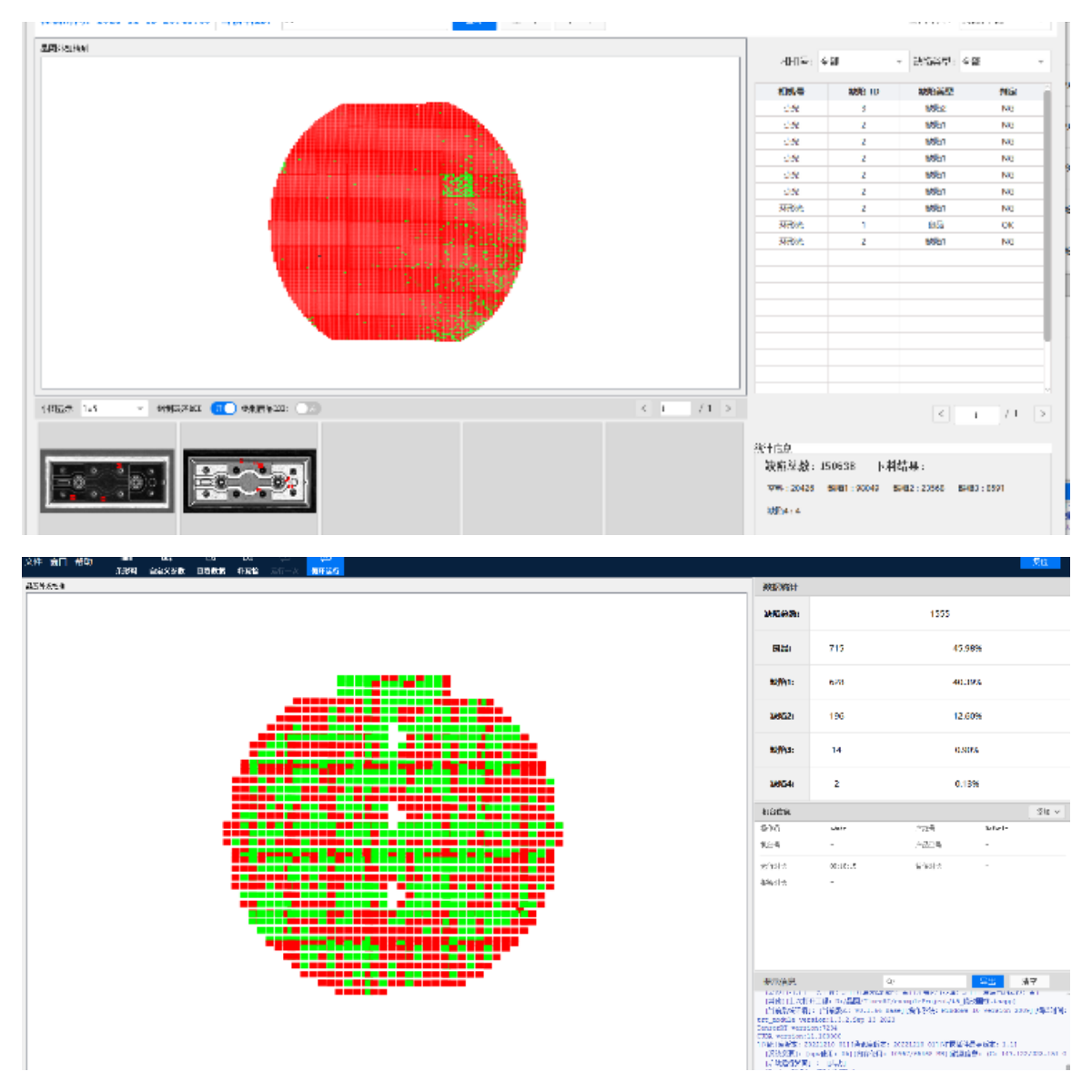

Functions for data statistics and analyses

Used for inspection and production process data statistics, provides a variety of Kanban templates; for the specified defect types or specified time period, provides a variety of yield statistics; provides a variety of data saving interface, production process traceability; for industrial scenarios, supports flexible and free configuration of the display unit, statistical indicators, the results of the query, export, upload logic; integration of a unified, visual multi-machine hardware interface debugging tools, so that the debugging process is more convenient.