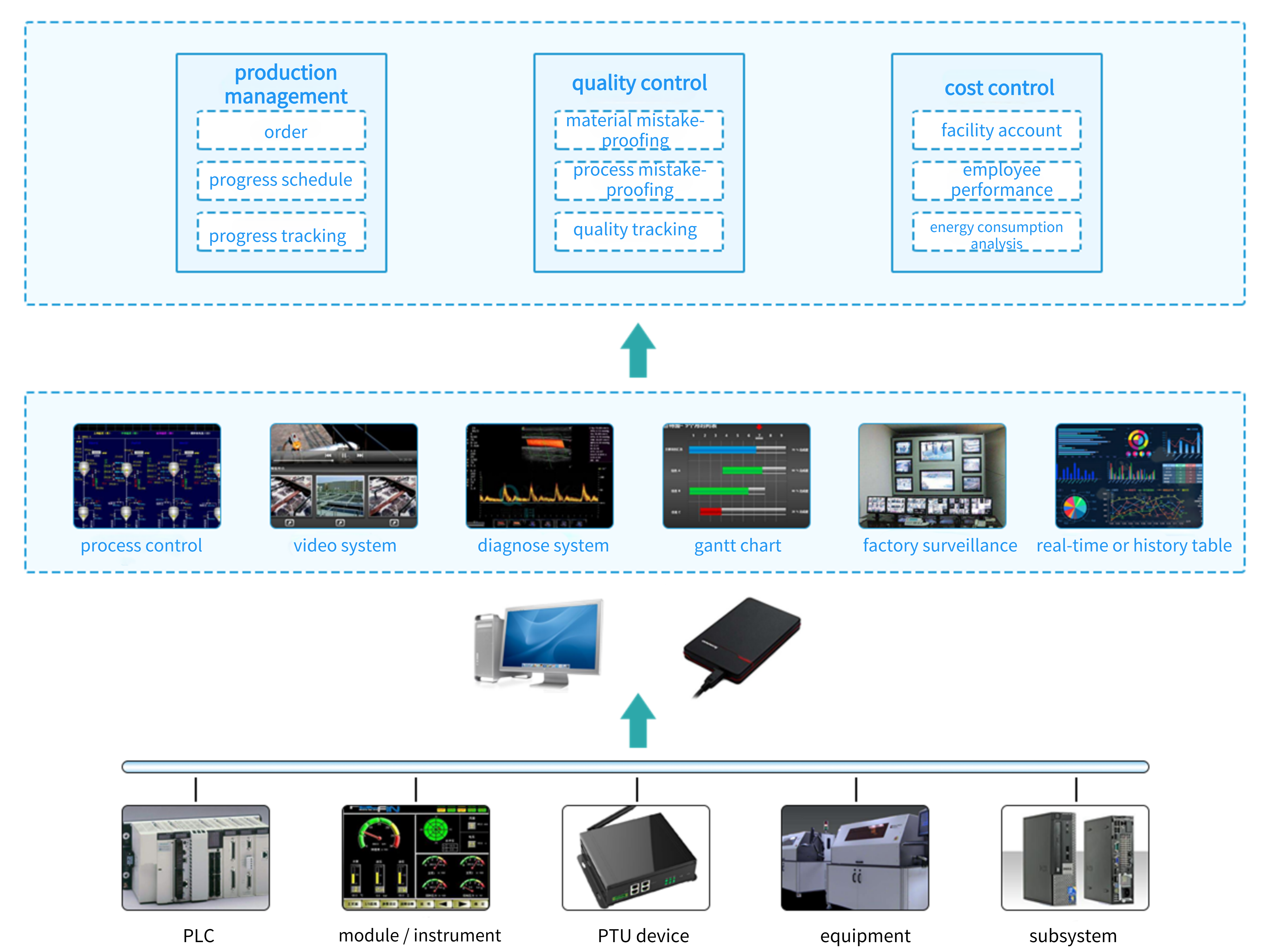

Data collection has always been the most practical and high-frequency demand in production and a prerequisite for Industry 4.0.

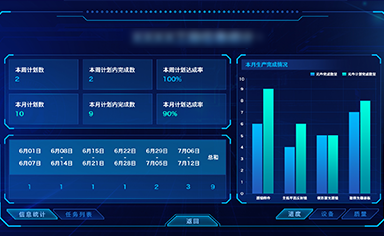

The equipment interconnection status monitoring system realises the collection, sharing, distribution, analysis and collaboration of equipment data, effectively improves

the traceability of product process parameters, provides help for management's production process monitoring and auxiliary decision-making, and provides data

support for the enterprise's intelligent manufacturing.