Currently, some processes in the manufacturing industry cannot be automated and need to be done manually. Manual operation has such problems as efficiency, large

differences in operating results, operating errors, etc., affecting quality, resulting in after-sales complaints, rework and a series of problems. Therefore, engineers and

enterprises hope to have a set of tools or systems to achieve real-time monitoring of production conditions and assembly actions, monitoring errors, eliminating

unnecessary wasteful actions, obtaining data and analyses to improve production efficiency, and real-time mastery of production conditions.

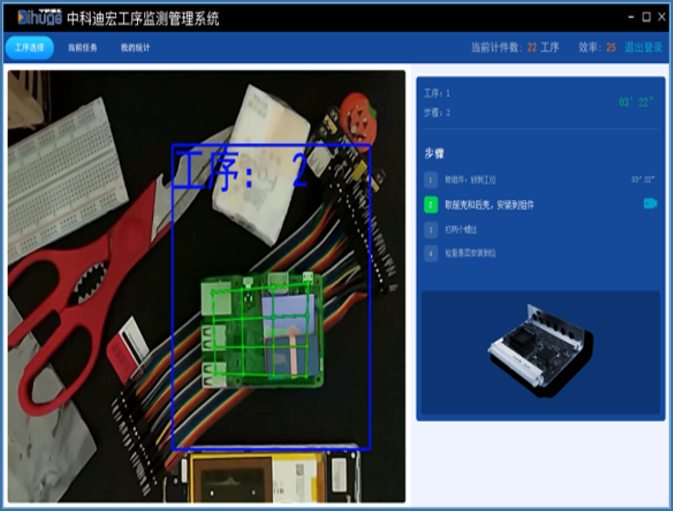

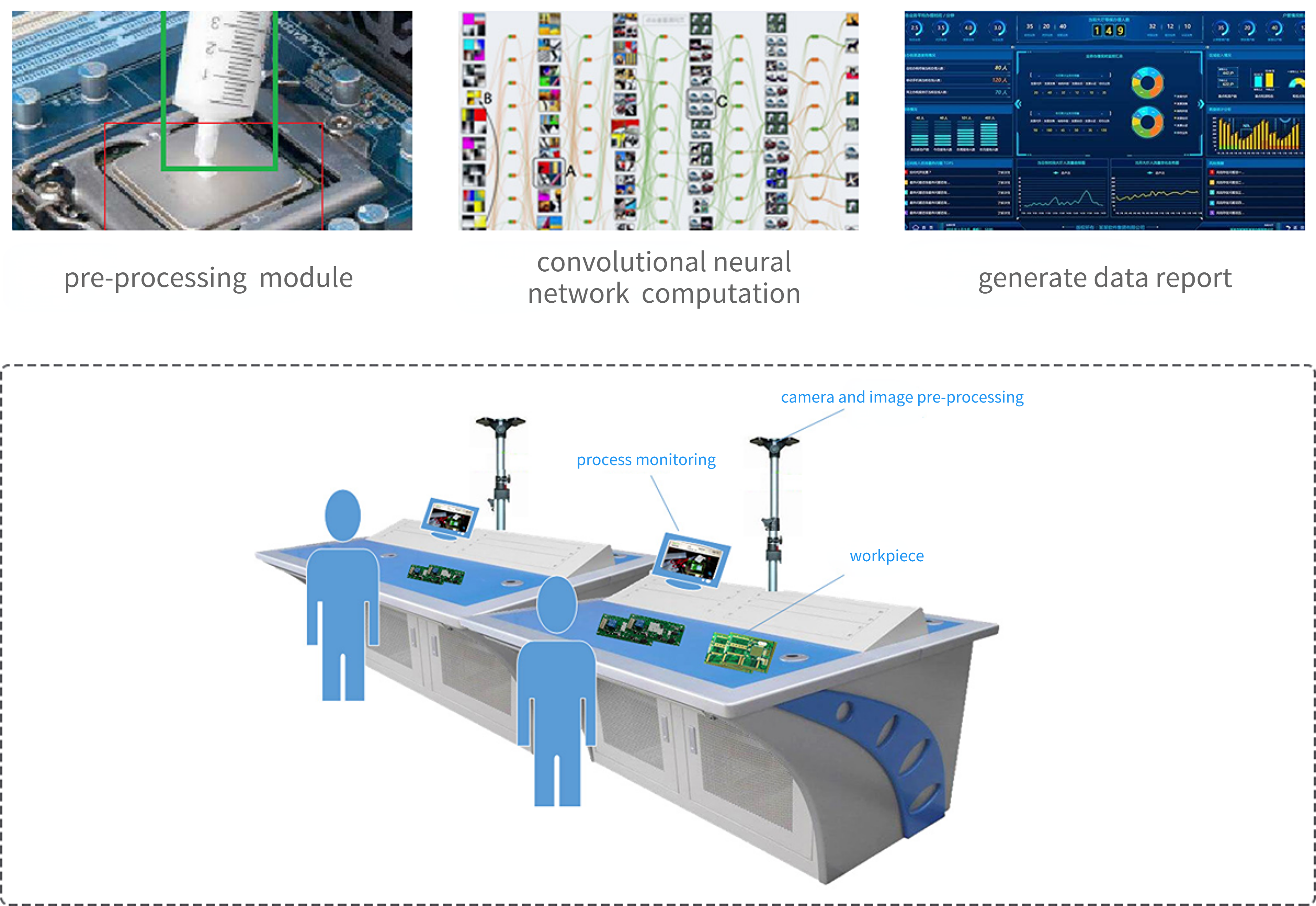

Dihuge process monitoring solution is mainly used to detect the real-time operation process of the workers at the workstation, monitor the operation errors, count the

average time of each process, provide data basis for the improvement of the quality and efficiency of the workstation, and verify the improvement efficiency, which is an

integrated system of quality control and overall labour productivity (OLE).