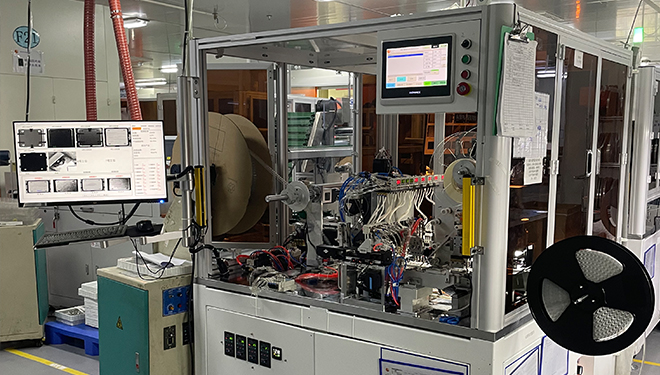

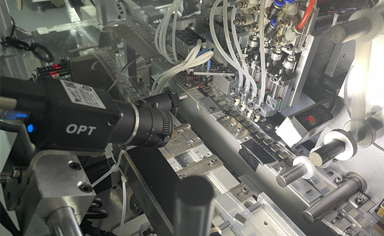

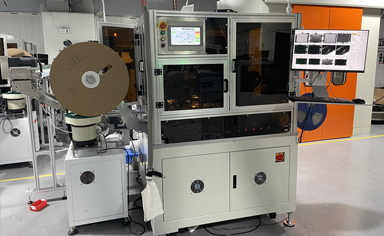

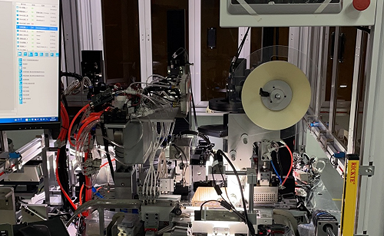

The shielding case cosmetic defects, 3D metrology and flexible packaging solution are based on Dihuge TimesAI deep learning development platform, integrating CV+AI+Automation to achieve online real-time detection of shield in precision cell phone parts, defect removal, data analysis and statistics in a one-stop service, and can be continuously optimized iteratively.

Effectively solved four major difficulties in the field:

First, there is a large difference in the probability of occurrence of different types of defects, and the defect samples are unbalanced.

Second, there is very little data on serious functional defects.

Third, there is a significant difference in the shape and extent of the same type of defect.

Fourth, defects are small target defects.

Currently, there are more than 15 types of defects covered, covering almost all defects of shield products, such as: Metal surface impression, metal surface scratch, metal surface dirt, metal surface impression, black membrane impression, black membrane scratch, black membrane dirt, black membrane damage, membrane bubbles, black membrane offset position, hole deformation, hole burrs, cracks, poor planarity, etc.