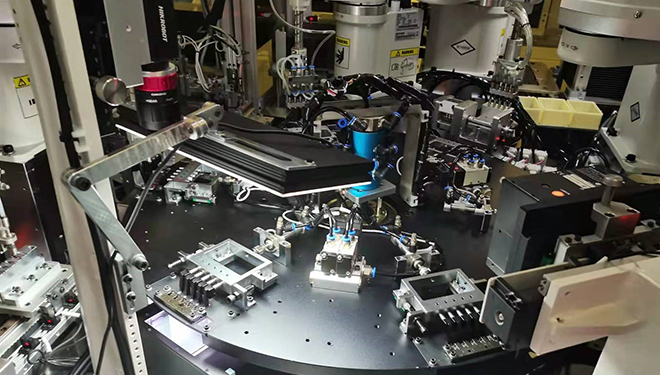

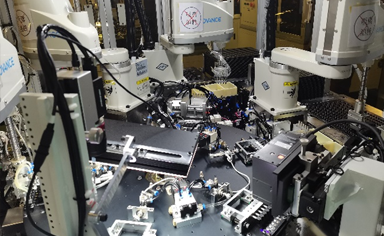

The acoustic metal part defect inspection and contour metrology solution is based on Dihuge TimesAI deep learning development platform, achieving the real-time detection requirements for the size and appearance of precision parts with laser engraved characters, as well as one-stop services for defect sorting and elimination, and analysis and statistics of detection data, which can be continuously optimized iteratively.

Effectively solved three major difficulties in the field:

1. The probability of occurrence of different types of defects varies greatly, and the defect samples are unbalanced.

2. Defects are small target defects.

3. Defect types have different semantic levels.

This solution mainly detects abnormal contour of acoustic metal parts and defects in laser engraving, as well as the mixing and shortage of materials in the production line.